Compatible with a wide range of spectroscopy applications and analyzers, HT1200I boasts several primates: it is leader in compactness and first to add support for sealed sample and solvent tubes. It offers short flow-path, a remarkable sample capacity and flexibility.

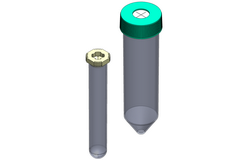

HT1200I offers the definitive answer to corrosion and bad smell issues by adding support to sealed samples and reagent tubes. The usage of sealed tubes helps to reduce the amount of chemical vapours in the environment, improve the quality of lab air and increase the lifetime of any object that could be affected by corrosion. The HT1200I is the first ICP autosampler to support sealed sample and reagent tubes, alongside standard open tubes.

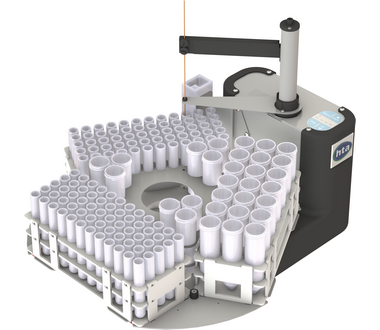

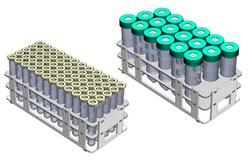

HT1200I holds 3 sample racks. Each rack has a consistent capacity to reach a remarkable total number of samples: up to 180 – when using 10ml - or 63 – when using 50ml - sample tubes. Conventional tube racks are supported to accommodate a wide range of sample tubes. For maximum flexibility, custom racks can be integrated to accommodate custom sample vessels. Mixed rack configuration are supported too.

The carousel and the arm – that holds the sample probe – rotate in order to align the first sample tube to be processed. The probe is then inserted at the programmable depth; at that point, the sample is aspirated by the analyzer through the inert flow-path. As soon as this task is completed, the probe is automatically moved to the washing port where the washing pump cleans the sample probe internally and externally in order to avoid cross contamination. HT1200I is then ready to process the next sample!

We typically run with a sample transfer tube 0.5 meter shorter than that of our competitors! That leads to a shorter sample rinse time, simpler/faster cleaning step and reduced bench space occupation: expect reduced argon and power supply consumption; expect longer lifetime of consumables like the tubings, the spray chamber and the torch as the contact time with the sample (matrix) is kept on a minimum level.

Through an encoder-driven solution, HT1200I prevents the time-based drift effect you may have experienced with other systems. A powerful ARM processor runs the HT1200I, allowing support of sophisticated algorithms – such as the automated calibration procedure, the management of external stresses and automatic recovery – while minimizing the electricity consumption.

Complete your evaluation! Get a Quote